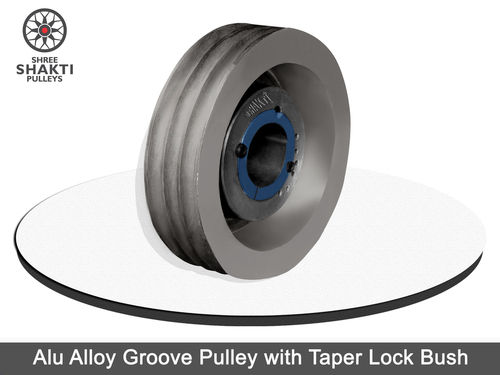

Aluminum Alloy Groove Pulley

Price 100.00 INR/ Piece

Aluminum Alloy Groove Pulley Specification

- Pulley Type

- Groove Pulley

- Features

- Lightweight, Corrosion Resistant, Durable Finish, Smooth Operation

- Power Source

- Manual/Mechanical

- Load Capacity

- 150 kg

- Bearing Type

- Sealed Ball Bearing

- Mounting Type

- Fixed Mount

- Lifting Height

- Adjustable as per requirement

- Application

- Lifting, Transmission, Industrial Machinery

- Sling Type

- Wire Rope/Cable Sling

- Diameter

- 100 mm

- Bore

- Precision Machined Bore

- Chain Length

- Customizable

- Number Of Grooves

- Single Groove

- Material

- Aluminum Alloy

- Surface Finish

- Anodized or Polished

- Groove Width

- 12 mm

- Working Temperature Range

- -20°C to 80°C

- Weight

- 0.85 kg

- Packaging Type

- Carton Box

- Groove Depth

- 10 mm

- Color

- Silver

- Rotation Direction

- Bi-directional

Aluminum Alloy Groove Pulley Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Payment Terms

- Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Western Union, Paypal, Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015 CERTIFIED COMPANY

About Aluminum Alloy Groove Pulley

We are an acclaimed manufacturer, exporter and supplier of Groove Pulley to our highly valued clients. It is fabricated by using the best quality raw material and machinery at our unit. This includes Graded Casting CI, Aluminum Alloy, Aluminum, and SG Iron. Our Groove Pulley is capable of maintaining both static and dynamic balance It is tested on various parameters to ensure adherence to the international quality standards. The special features of this product are its high strength, availability in different specifications and low maintenance cost.

Different types of Groove Pulley available with us for different industries are as follows:

- V Groove Pulley

- Solid V Groove Pulley

- Split V Groove Pulley

- Multi Groove Pulley

- Taper Lock V Groove Pulley

Engineered for Reliability and Versatility

Designed to meet demanding industrial needs, this groove pulley offers superior strength despite its lightweight 0.85 kg build. The bi-directional rotation and fixed mounting type allow for easy installation and dependable operation in various lifting and transmission setups. Its sealed ball bearing enhances longevity and ensures smooth, maintenance-free usage.

Superior Surface Finish for Maximum Protection

Choose between anodized or polished finishes for confidence in durability, corrosion resistance, and a sophisticated appearance. The surface treatments not only extend the pulleys service life but also contribute to friction reduction, supporting smooth, quiet performance within its broad working temperature range.

Customizable to Your Project Requirements

Our pulley accommodates specific user needs, such as chain length and lifting height adjustments, making it perfectly suited for unique lifting scenarios or integration into industrial machinery. The wire rope or cable sling compatibility broadens its field of applications, ensuring efficiency and safety.

FAQs of Aluminum Alloy Groove Pulley:

Q: How is the Aluminum Alloy Groove Pulley installed in lifting or transmission applications?

A: This pulley features a fixed mount design and precision-machined bore, allowing for straightforward installation on compatible shafts or frameworks. It integrates seamlessly with wire ropes or cable slings, making setup quick and secure in both manual and mechanical operations.Q: What benefits does the anodized or polished surface finish offer?

A: Both surface finishes provide superior defense against corrosion, prolonging the pulleys lifespan. Anodizing delivers an extra layer of protection, while polishing enhances the smoothness for even quieter, low-resistance operation in demanding conditions.Q: Where can this groove pulley be used most effectively?

A: Its ideal for lifting, transmission, and industrial machinery operations. With support for wire rope/cable slings and a robust load capacity, its highly suited for environments like factories, warehouses, or construction sites requiring reliable material handling solutions.Q: What is the process for customizing the chain length or lifting height?

A: You can specify the desired chain length and lifting height at the time of order. Our team will tailor the assembly to fit your applications specific requirements, ensuring precision and safety in your lifting setup.Q: How does the sealed ball bearing enhance pulley performance?

A: The integrated sealed ball bearing minimizes friction and shields internal components from dust and contaminants. This ensures smooth bi-directional rotation and extends bearing life while reducing maintenance demands.Q: When should I choose this pulley over other material options?

A: If lightweight strength, corrosion resistance, and smooth operation are crucial for your application, this aluminum alloy groove pulley is preferable. It is especially suitable where weight reduction and durability are important, such as in mobile lifting gear or industrial conveyors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pulleys Category

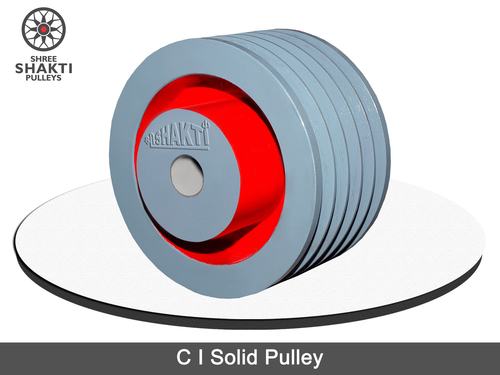

Solid Flat Pulley

Price 4500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : INDUSTRIAL

Product Type : C I SOLID FLAT PULLEY

Color : AS SHOWN IN PHOTO.

Size : 8" DIA X 5" WIDTH X 42mm Bore

Multi Groove Pulley

Price 74999.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : PELLET MILL PULLEY

Product Type : C I V GROOVE PULLEY

Color : AS PER IMAGE

Size : 960mm Dia X C11 Groove

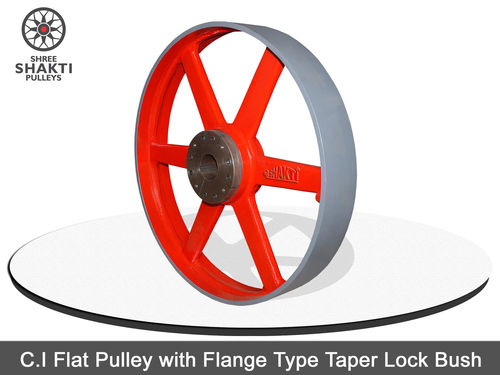

Cast Iron Pulley

Price 5000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial Use

Product Type : Cast Iron Pulley

Color : Any

Size : 03 To 100 Inch

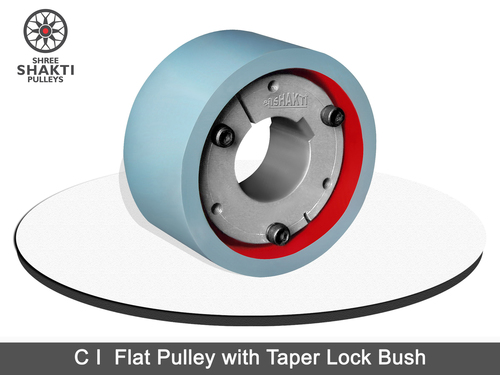

Taper Lock Flat Pulley

Price 55000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : INDUSTRIAL

Product Type : C I FLAT PULLEY WITH TAPER LOCK BUSH

Color : AS PER IMAGE

Size : 1120mm Dia X 200mm Width X 85mm Bore

|

SHREE SHAKTI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry